🛠️ Retrofitting for Performance & Cost Savings

We help our customers reduce operational expenses by improving existing equipment — increasing productivity while avoiding the cost of full system replacements.

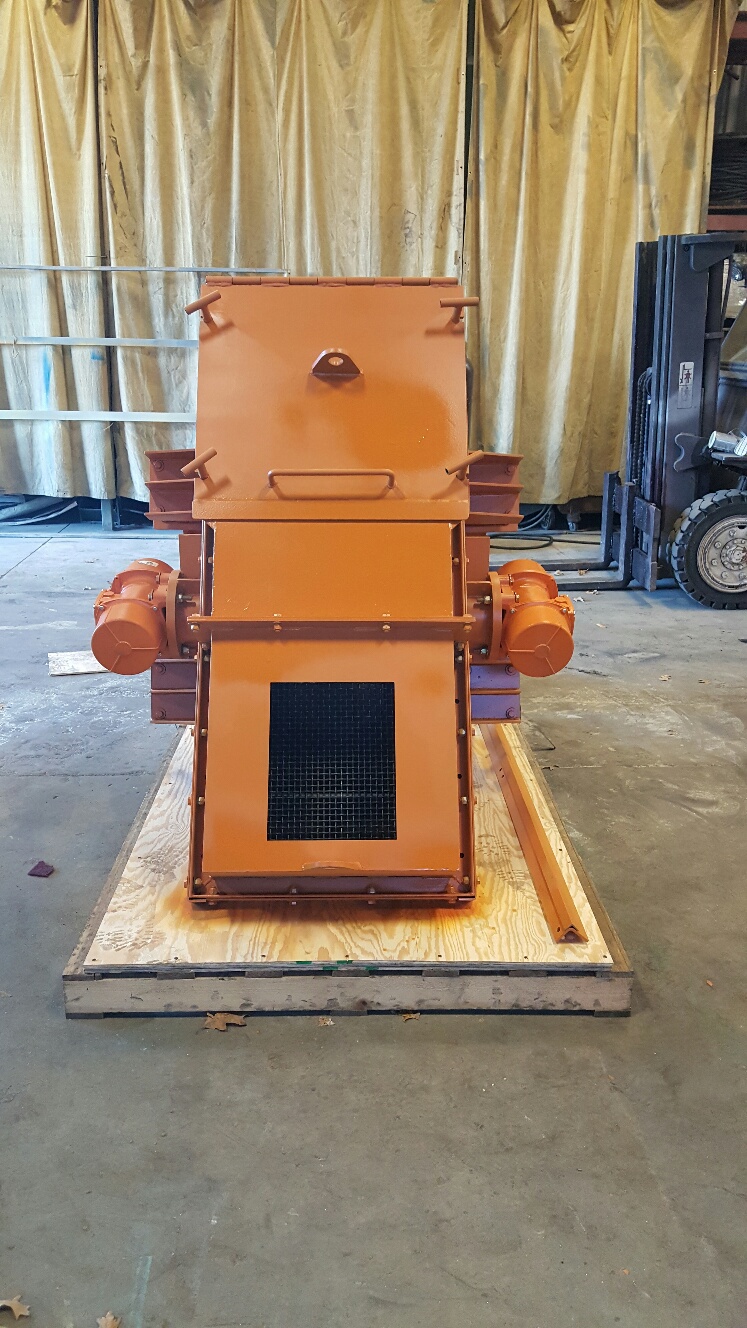

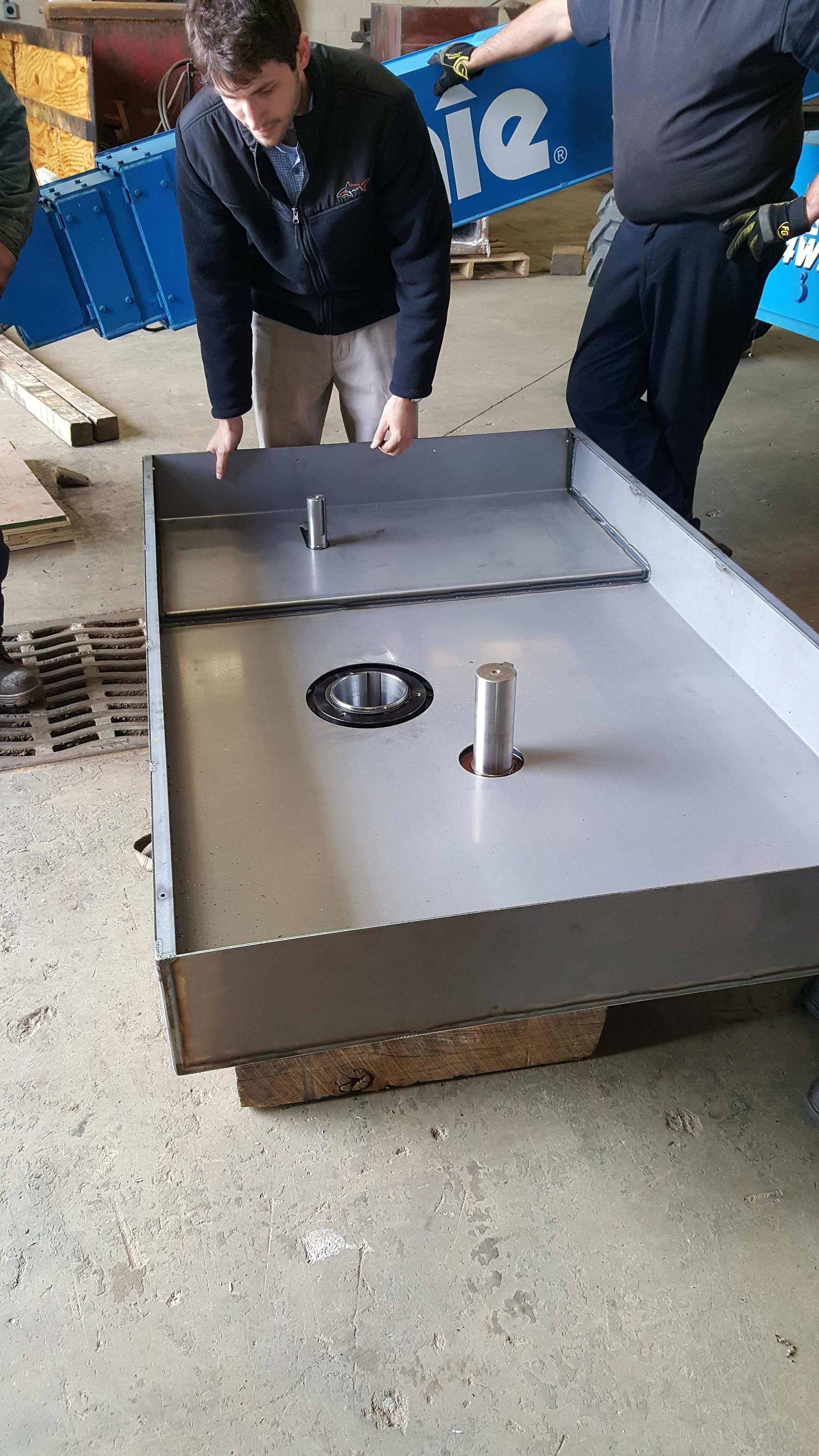

Project: Vibratory Feeder & Load Zone

Project No.: PJ15-016

Industry: Manufacturing

Material: Roofing / Asphalt Granules

Customer Challenges:

Excessive dust in the load zone

Spillage at the conveyor tail

Material build-up causing premature component wear

Our Solution:

Conducted 3D laser scan of site

Delivered concept drawings and 3D models

Provided full design drawings, overlaid with scan data for precision

Created parts list for procurement

Fabricated custom vibratory feeder & load zone

Provided installation guidance and remote support

ROI Highlights:

Reduced splash loading by centering material load

Extended load zone minimized dust and spillage

Cut labor costs with reduced cleanup

Increased uptime and operational efficiency

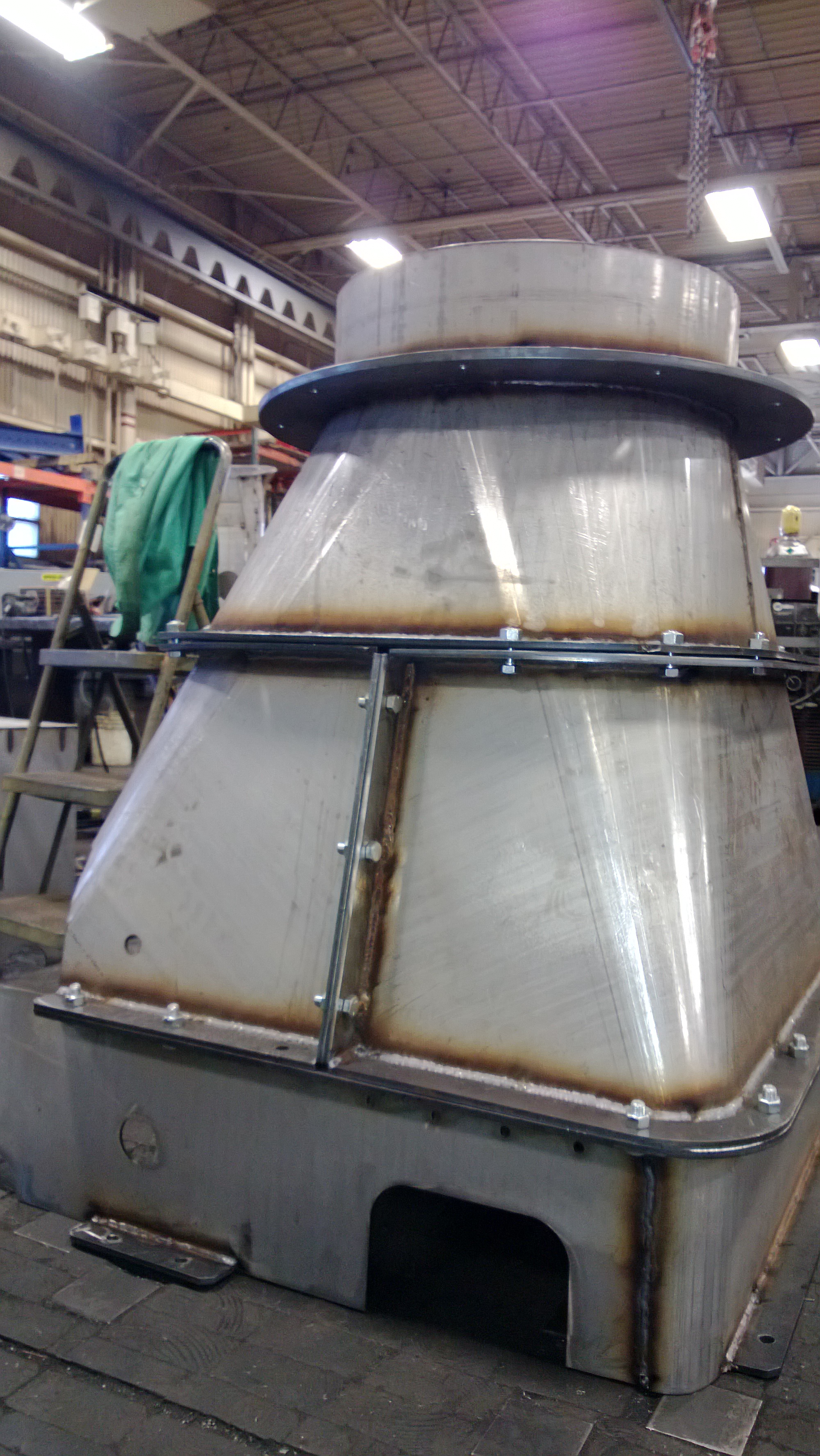

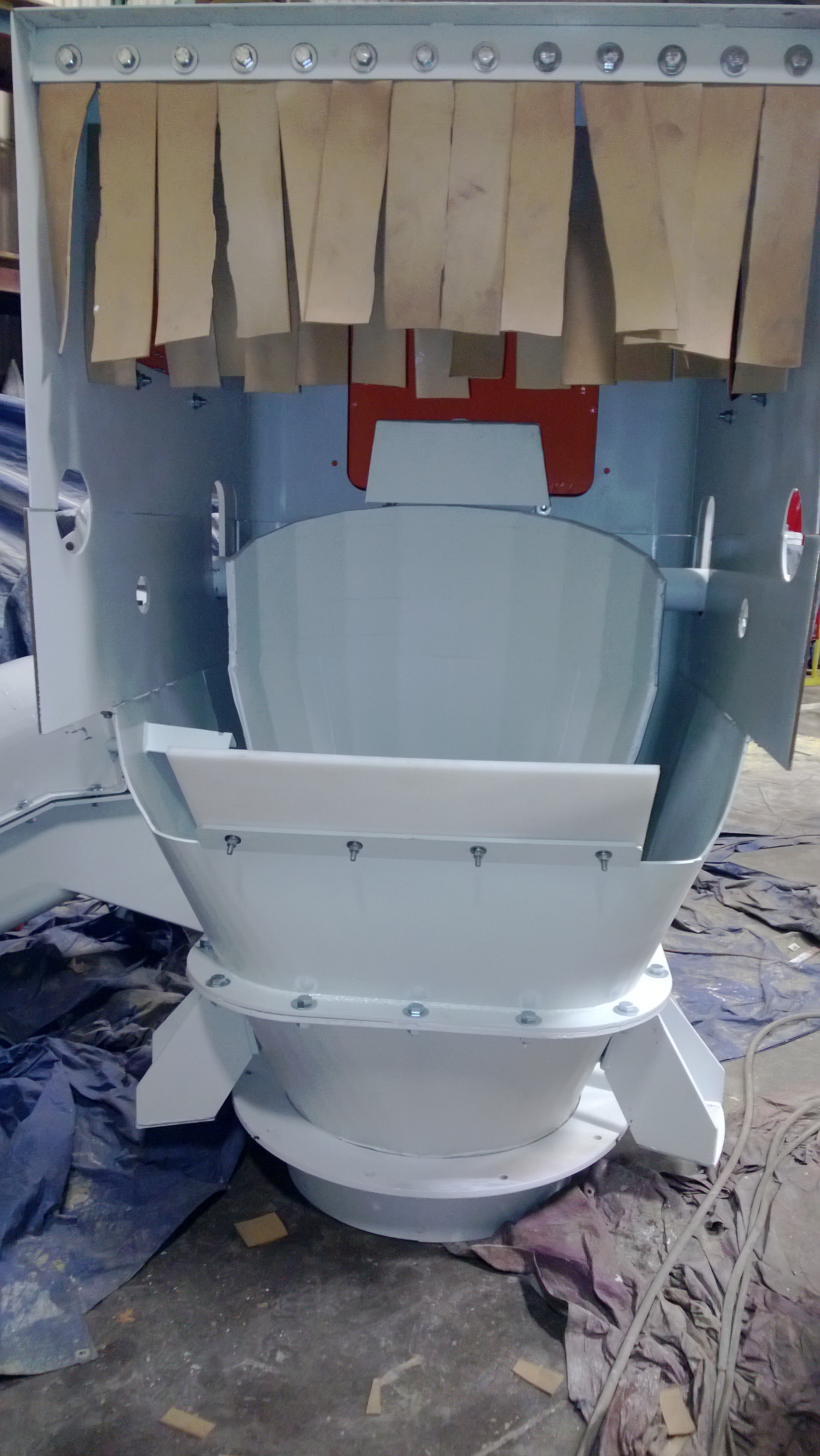

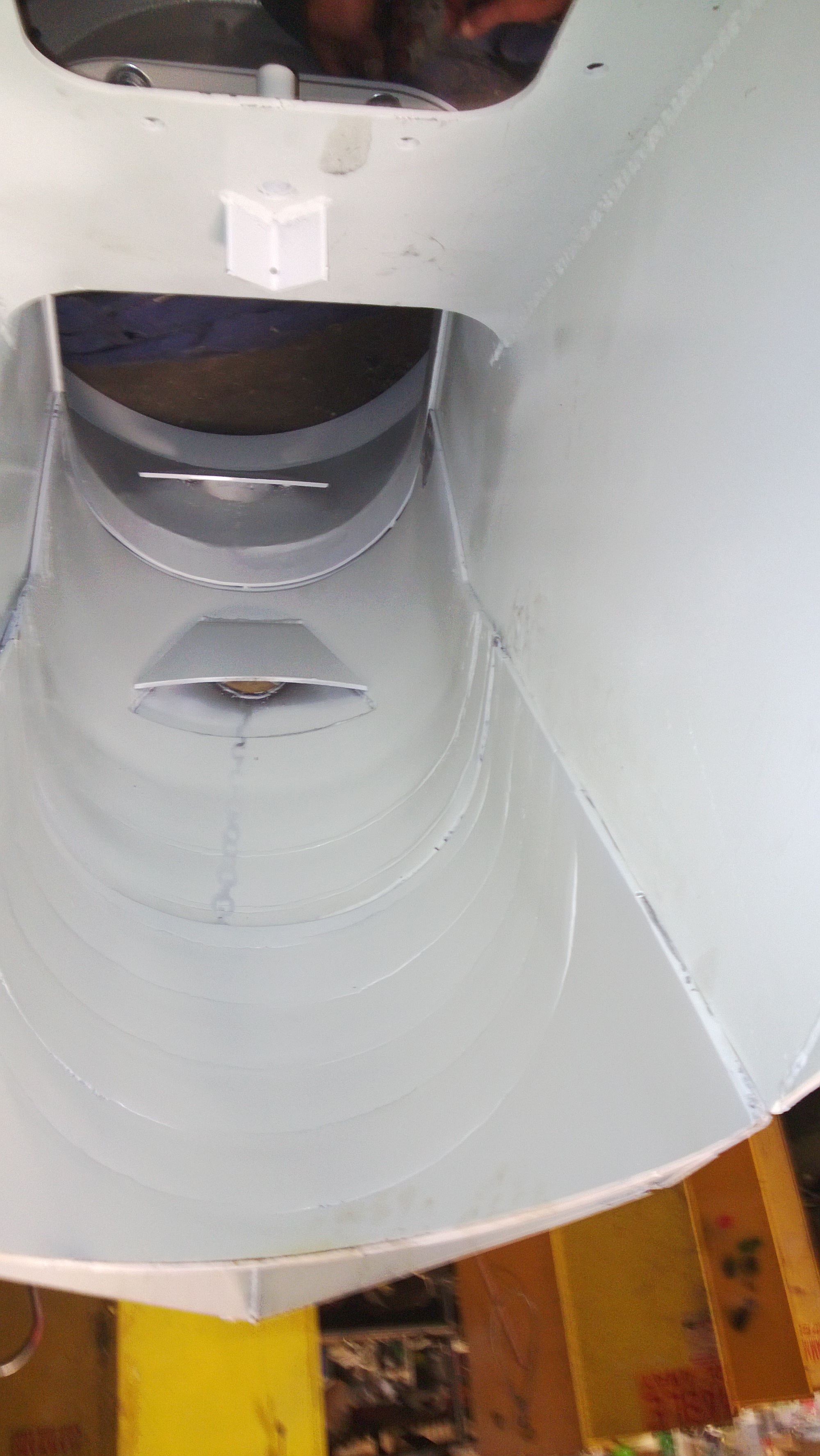

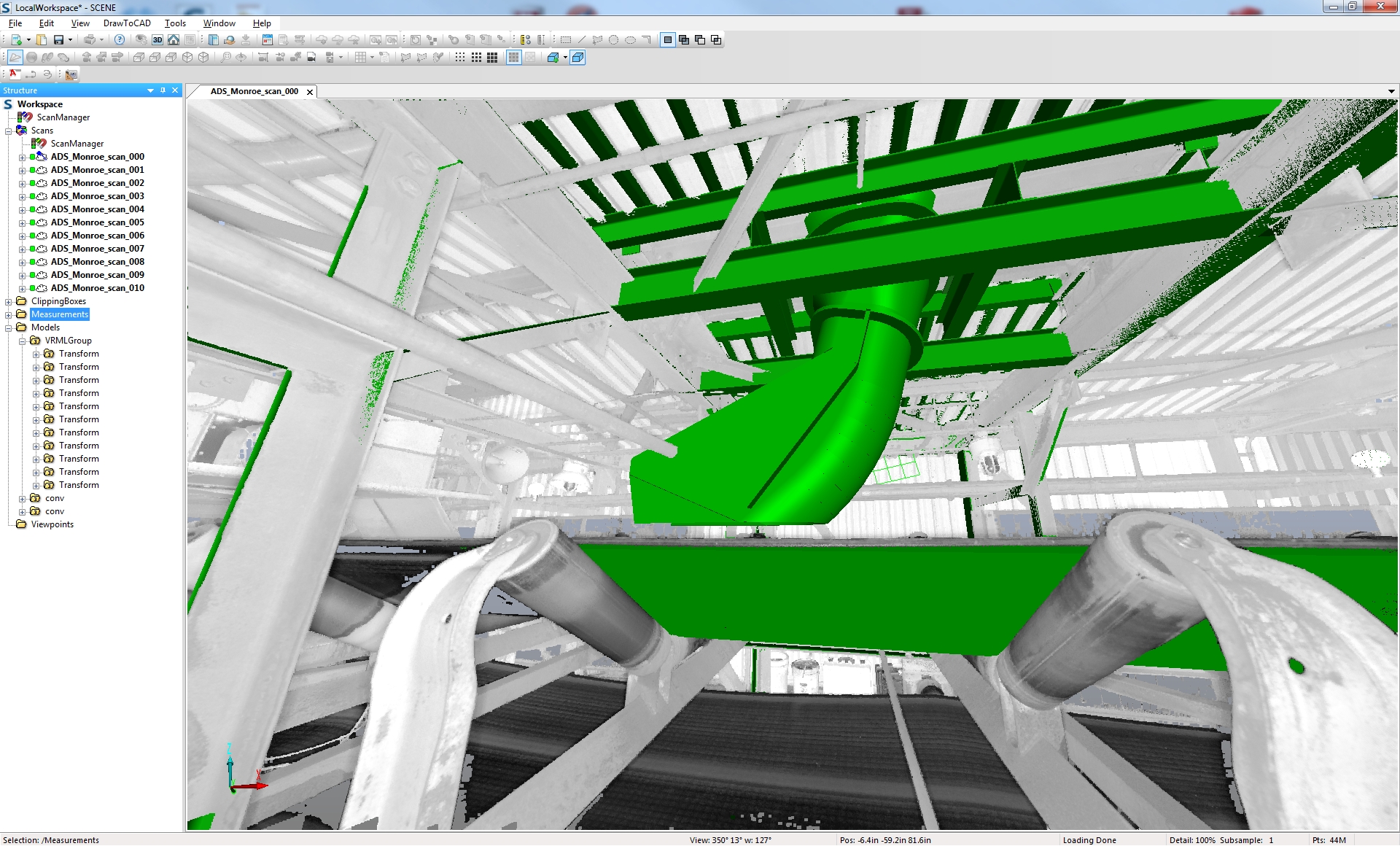

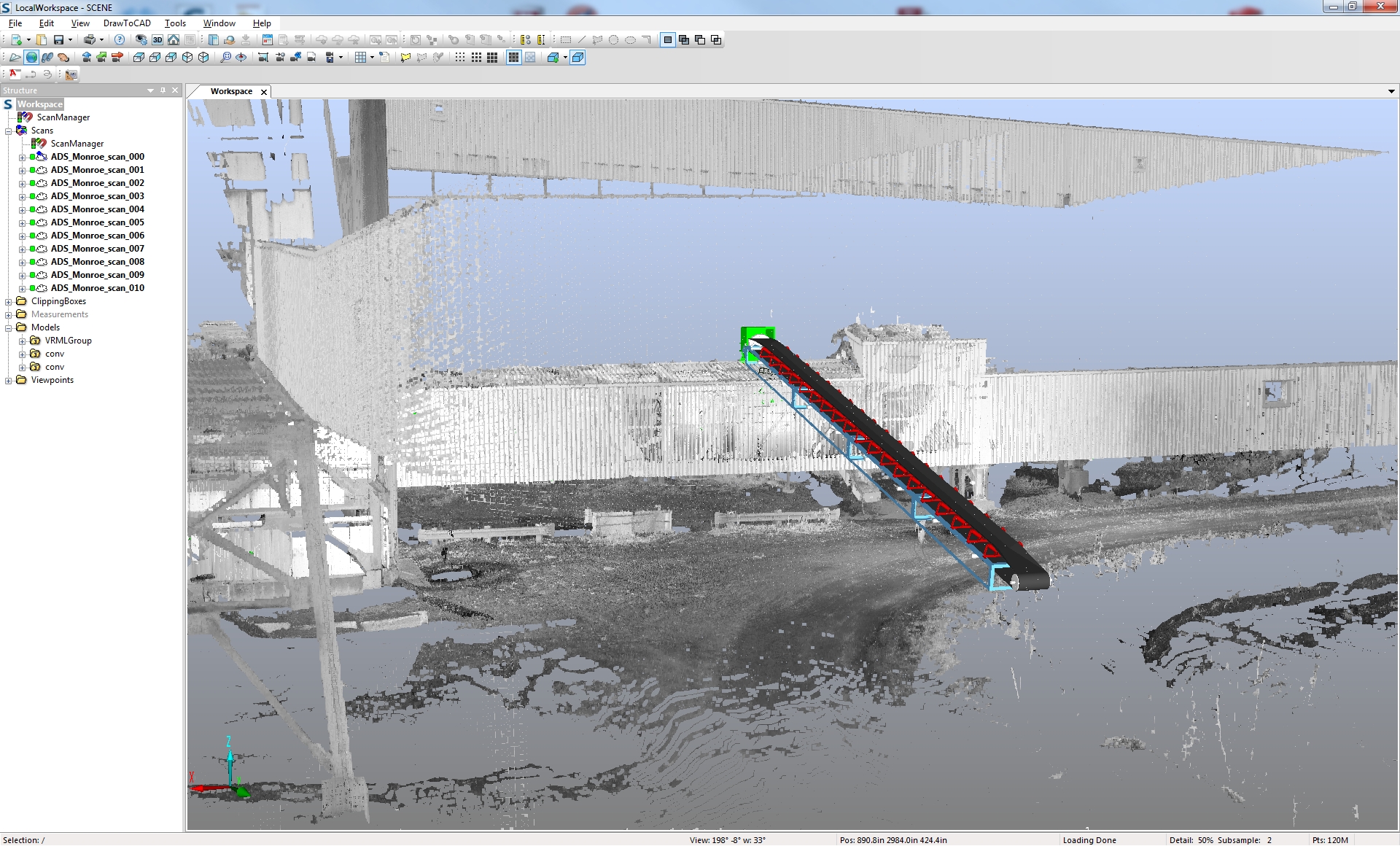

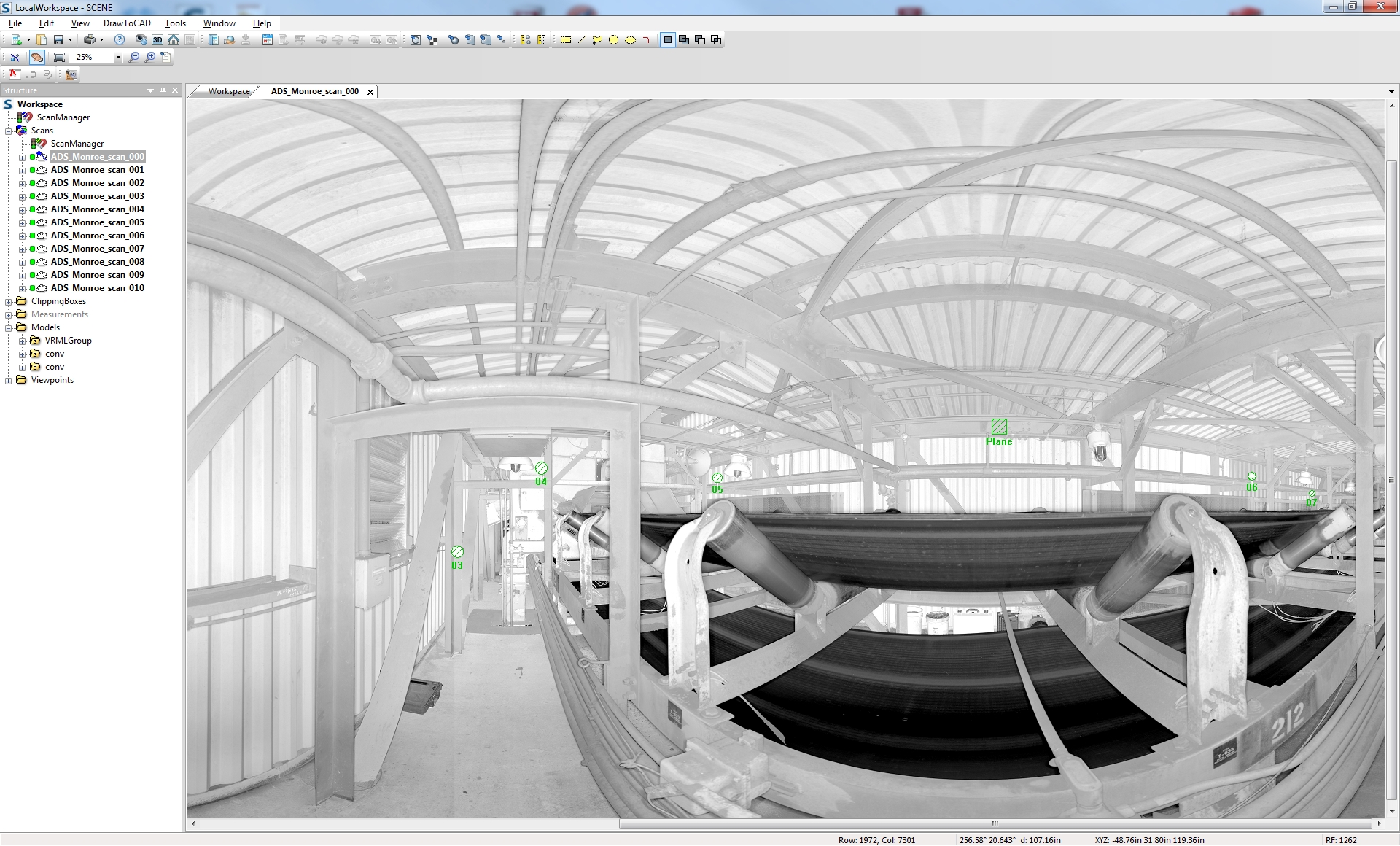

Project: Transfer Chute System

Project No.: PJ13-033

Industry: Power Generation

Material: Petroleum Coke

Customer Challenges:

Needed a temporary transfer system to integrate with existing equipment

Required precise delivery with minimal dust or spillage

Design had to be adaptable to a permanent future system

Our Solution:

Completed site survey and discovery

Performed 3D laser scanning and DEM flow analysis

Designed system using 3D solid modeling

Checked new design fit against existing structures using scan overlays

Created a visual site viewer for stakeholder review

Fabricated and pre-assembled system components before scheduled outage

Supported exact-fit installation during outage window

ROI Highlights:

Early identification of structural interferences saved outage time

2-hour installation with zero fit-up issues

Dust and fugitive material controlled to acceptable levels

No additional maintenance required post-install

Project: Conveyor Drive & Motor Upgrade

Project No.: PJ15-061

Industry: Power Generation

Material: Limestone

Customer Challenges:

Conveyor drive was underpowered

Belt could not start from a dead stop under load

Our Solution:

Supplied complete drive assembly:

Shaft-mounted gearbox

10 HP motor

Custom guarding

Bushings, torque arm, v-belts, sheaves, and backstop

Pre-assembled components for quick installation

Provided full documentation and installation instructions

ROI Highlights:

Eliminated risks of incorrect or missing parts

Restored start/stop functionality under full load

Enabled reliable throughput without motor damage