Our approach: practical Solutions, Not unnecessary products

We specialize in identifying and correcting the root causes of material flow issues of Bulk Material Handling Systems (BMHS) — not in selling off-the-shelf equipment that may not address the problem.

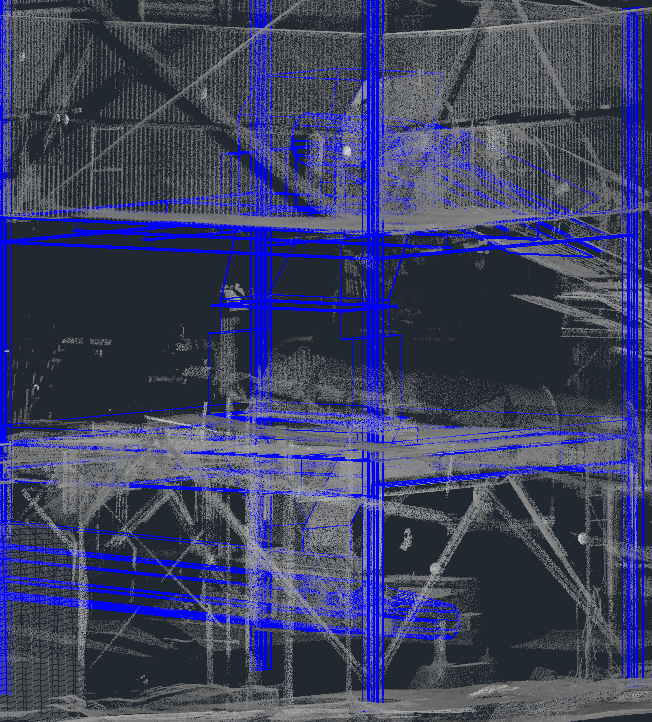

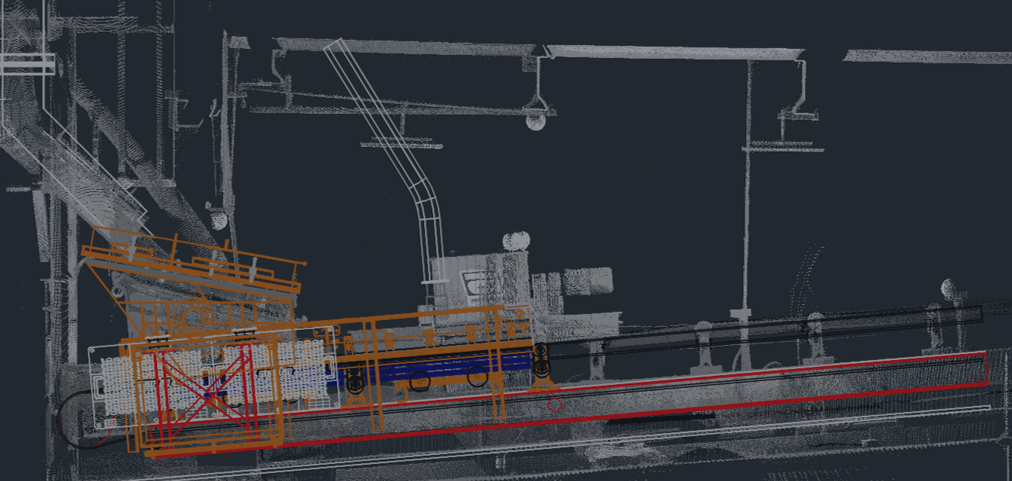

Data collection

We leverage high-precision 3D laser scanners to capture comprehensive imaging, measurements, and inspection of complex industrial structures. These scanners gather millions of data points, which are stitched together to create a detailed and accurate model of your job site.

Beyond scanning, we collect critical data including:

Material Property and flow behavior

Conveyer belt types and conditions

Equipment specifications(gates, chutes, feeders, etc.)

Environmental factors that influence operation

Our method uncovers site realities that traditional drawings often miss—such as structural changes, clearance issues, electrical routing, and component wear— preventing costly problems later in the project.

System Study & Risk Assessment

Our system evaluations reveal and predict potential issues with:

Overloaded or mismatched conveyers, crushers, stackers, screens, feeders, and reclaimers

Poor material flow in hoppers, silos, chutes, grizzlies, and gates

Premature component wear

Spillage and fugitive material

Improper belt loading and carryback

Dust creation and combustible dust risks

Belt tracking and misalignment

OSHA/MSHA compliance for guarding and walkways

Material flow analysis

We use advanced simulation tools and discrete element modeling (DEM) to analyze material behavior under realistic operating conditions. By factoring in physical properties — friction, cohesion, gravity, electrostatics, magnetism — we simulate how materials move and interact with system components.

Our DEM software provides:

Velocity and force visualization

Particle trajectory modeling

Identification of high-wear areas

Off-center loading or plugging risks

This data-driven insight helps avoid common design flaws and improves equipment life.

Retrofit component design & supply

With over 30 years in material handling, we engineer and fabricate custom retrofit components tailored to solve specific site issues. Our designs are:

Site-specific and application-driven

Fabricated to fit with no or minimal field adjustment

Easy to maintain and install

Built to reduce critical outage time

Whether it’s a chute, belt cleaner, or transfer point, our components are engineered with accuracy and intent — not guesswork.